| Specifications | ||

| Model | ||

| Set weight | 20~30kg/ bag | |

| Bag type | ||

※2 | 380 to 460 mm | |

| 1.5kW | ||

| Machine weight | ||

match

Outline dimensional drawing |

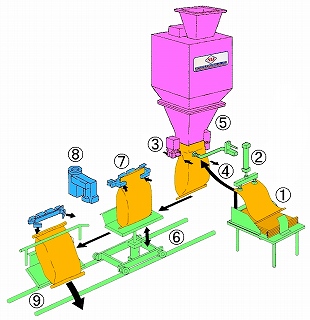

Name of each part | ||

① Bag supply department Place the mouth of the bag outward and correctly. It can carry about 50 bags. ② adsorption part Remove the bag one at a time, rotate it 90 degrees and place it in the filling section. ③ Clamping part Clamp the sides of the bag. The width of the fixture used is 30mm. ④ opening part Suction cups are used to attract openings from both sides of the bag. (Use vacuum generator) to ensure adequate timing. ⑤ Filling part Smooth filling of product with expansion nozzle. ⑥ Car, foot slide At the beginning of filling, the cart moves from a fixed position towards the hopper side. Lift the bottom of the bag with the bottom plate, seeking to promote filling. ⑦ Plastic bag que After pleating, clamp the bag with the pressure bar on the side of the hopper and the pressure bar on the side of the trolley to shape the mouth of the bag. The bag is carried by cart to the sewing machine with a bag claw on the side. ⑧ Sewing Machine Department (DS-6AC) When bags are detected on a walking trolley, the sewing machine will start. At the same time, the bag que claw opens the bag. The edge of the bag is detected, and the machine is finished. ⑨ Emissions When the trolley reaches the fixed position and stops, tilt the base plate of the bag bottom to make the bag slip and discharge. | ||

| ||