Product Parameters

| Standard specification | PBC-S | PBS-S | PBC-3W | PBS-3W |

| Bag type | Three layers of kraft paper (with Angle brace) | Three layers of kraft paper (with Angle brace) | Three layers of kraft paper + poly inner layer | Three layers of kraft paper + poly inner layer |

| Sealing speed※ (m/min ) | 6~14 | 6~14 | 6~12 | 6~12 |

| Folding depth(mm ) | 45 | 45 | 50 | 50 |

| power( kw ) | 0.75 | 0.4 | 0.75 | 0.4 |

| air(NL/min ) | 400 | 400 | 800 | 800 |

Heater capacity

( kw ) | C=3kW | C=3kW | A/B/C= 3kW each (Total 9kW) | A/B/C= 3kW each (Total 9kW) |

Sealer dimensions

| Length(mm ) | 2,320 | 1,975 | 3,424 | 3,290 |

| breadth(mm ) | 1,250 | 1,515 | 1,280 | 1,113 |

| Altitude(mm ) | 1,752 | 1,880 | 1,790 | 1,800 |

| Sealer gross weight (kg) | 280 | 300 | 480 | 500 |

| Measurements (cft) | 200 | 200 | 220 | 220 |

| Shipping weight(kg) | 550 | 550 | 1,250 | 1,250 |

Product size*The dimensions in the picture vary depending on the specifications。

Outline dimensional drawing |

PBC-S

PBC-3W

PBS-3W

{pboot:if('Single/double pocket carrier chain typeUnpack the double clip bag into a compact V-band shapePinch feed bag (single pinch feed) Bend the upper front end of the pinch bag 90 degrees and dissolve the hot melt adhesive part with hot air from the warm air heater. Bend again 90 degrees and seal with crimping tape. _______________ poly inner bag (double bag) Preheat with inner layer The air heater first preheats the inner layer of polyethylene inside, and then seals the inner seal with the heater part. Also, the heat above the bag dissolves the melt with the hot air of the warm air heater and is completely sealed. _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ u●Carrier chains hold the bag top firmly and traverse throughout the process with the bag held, preventing slippage of sealing position.● The inner PE is perfectly sealed using the pre-heaters and heater bars of the PBC-3W.●The warm air heater will bend the mouth of the bag 90 degrees, use the warm air heater to dissolve the hot melt adhesive part, and then bend 90 degrees.●The press belt is pressed and cooled through the stamping belt, and the bag mouth is closed.●The upper and lower parts of the optional (electric upper and lower) sealing seals can be pressed from the operating side with buttons.●A typewriter (optional) is an automatic ink printer that is printed with a press sealer. The type change is also very simple with the microswitch's single-coil clutch printed in a fixed position.'!='')}

Product Details

{pboot:2if(''!='')}

{2else}

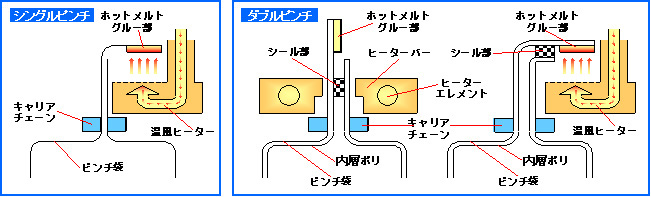

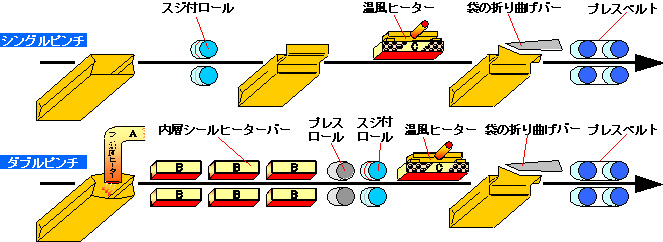

Single/double pocket carrier chain type

Unpack the double clip bag into a compact V-band shape

Pinch feed bag (single pinch feed) Bend the upper front end of the pinch bag 90 degrees and dissolve the hot melt adhesive part with hot air from the warm air heater. Bend again 90 degrees and seal with crimping tape. _______________ poly inner bag (double bag) Preheat with inner layer The air heater first preheats the inner layer of polyethylene inside, and then seals the inner seal with the heater part. Also, the heat above the bag dissolves the melt with the hot air of the warm air heater and is completely sealed. _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ u

|

|

|

|

|

{/pboot:2if}

{else}

{/pboot:if}