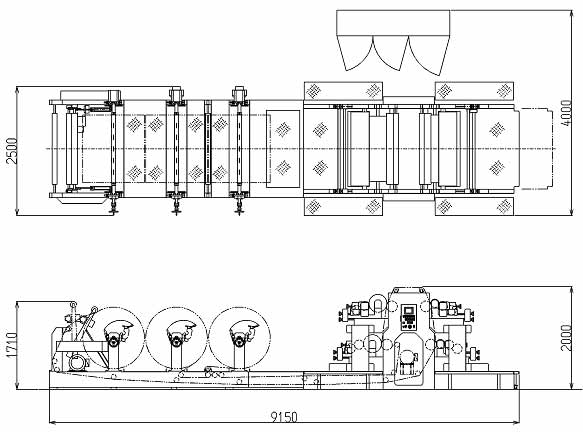

| specification | |

| Model number | FZ400 |

| Color number | 4 |

| Printing width | Max 1220mm |

| Print length | 20 "~43" (508-1092.2mm) [0.5 "step length] |

| Base paper width | Max 1320mm |

| Base paper diameter | Max 1200mm |

| Base paper base weight | 60~110g/㎡ |

| Machine speed | Max 180m/min |

dimension |

| List of options | |

| ● | The vertical printing position of the electric longitudinal differential unit can be adjusted by remote control. |

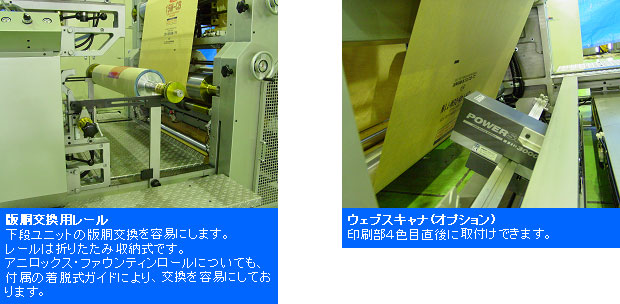

| ● | Web scanner Because it is installed immediately after the fourth color of the print section, the print status can be determined in real time. |

| ● | The 3rd and 4th color units of the roller reversing device can effectively prevent entanglement during cleaning. |

| ● | Ceramic mesh roller Mesh roller has a long service life and is especially effective when using a scraper. In addition, the larger the cell size and the more rows, the more you can take than usual. |

| ● | Ink chamber scraper system for high precision dot printing, such as process printing. |

| ● | Ink cartridge Teflon coating helps clean ink cartridges. |

| ● | Paper feeder makes it easier to transfer paper from the entrance to the exit of the printed part. |

| ● | Set plate body |