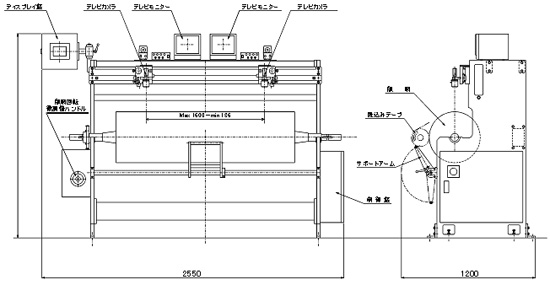

| specification | |

| Plate circumference | 450~1350mm |

| Maximum version body length | 1550mm |

dimension |

○ Dimensions vary according to specifications.

| trait | |

| ● | Simply align the marks on the left and right sides of the printing plate with the guides on the two TV monitors. |

| ● | Compared with the traditional half mirror method, the working time is greatly shortened (1/3~1/5). |

| ● | The registration accuracy is very good within 0.1mm. |

| ● | It is easy to operate and does not require any skill. |

| ● | Plate cylinder rotating electric, positive and negative rotation can be fine-tuned. |

routine | |||

| 1. | Set the cylinder and install the drive gear. | 5. | Move the left and right cameras according to the distance between the registration marks on the plate. |

| 2. | Attach double-sided tape to the place where the printing plate will be installed. | 6. | Temporarily place the printing plate on the printing plate body, and adjust the zoom, focus, spotlight exposure range of the camera. |

| 3. | . Input the repeat value of the board cylinder on the display panel and reset it to zero at the adhesion reference position in the circular direction of the board | 7. | Tear off the release paper of the double-sided tape and paste the plate to the position where the cross line of the TV monitor and the print register mark are superimposed. |

| 4. | At the reference position in the board width direction, the left and right camera moving distance is reset to zero. | 8. | After installing the plate, remove the drive gear and remove the plate barrel from the aircraft. |