| Model number | TS2746 | TS2755 |

| Bag width | 180 - 460 | 220 - 550 |

| Cutting length | 360 - 770 | 360 - 770 |

| Bottom width | 80 - 220 | 80 - 220 |

| Base paper width | 1390 | 1570 |

| Capacity [bags/min] | 180 | 170 |

| Circular band unit(H) | H607 | H607 |

| Handle patch cut length | 190.5(7.5) | 190.5(7.5) |

| Bag width (shopping bag) | 220 - 460 | 220 - 550 |

| Bag bottom width (shopping bag) | 80 - 220 | 80 - 220 |

| Cut length (shopping bag) | 360 - 650 | 360 - 650 |

| Between handle centers | 320 - 680 | 320 - 770 |

| Handle length | 400 | 400 |

| Flat string unit (FH) | H707 | 518 |

| Bag width (shopping bag) | 200 - 460 | 220 - 550 |

| Bag bottom width (shopping bag) | 80 - 220 | 80 - 220 |

| Cut length (shopping bag) | 360 - 770 | 360 - 710 |

| Between handle centers | 280 - 680 | 380 - 760 |

| Handle length | 324 | 370 |

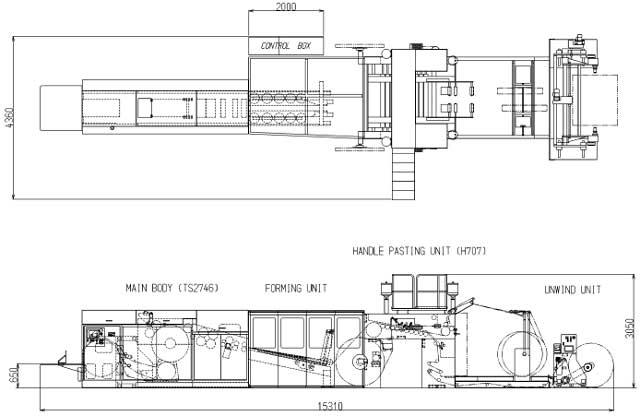

dimension |

-

This is the size drawing of TS2746FH.

○ Dimensions vary according to specifications

|

Round chord

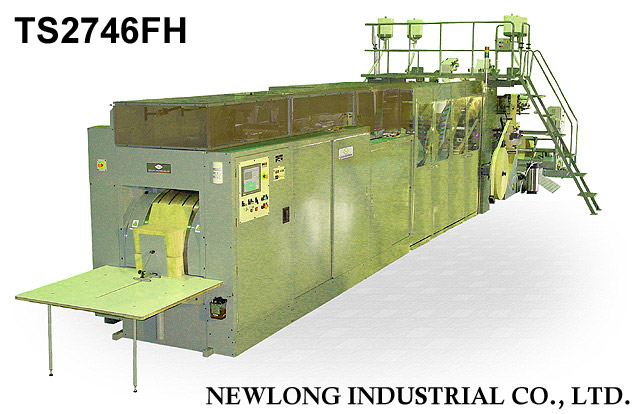

| This is a square bottom bag making machine that makes full use of NLI technology. We have achieved NC of grip relationship and cutting length, which takes time when changing the mold. Execute a series of NC control projects simultaneously. · Base paper positioning Base coil correction sensor positioning · Glue positioning with handle (patch glue) · Handle attachment positioning · Servo control of handle-mounted press · Position handle to center · Molding plate positioning · Hydarol location · Cutting length servo control · Automatic adjustment of cutter speed · First muscle positioning ○NC control items can be fine-tuned during operation. |