Specifications | |

| Model | HP9060FS/FL |

| Performance | >70 injections/min |

| Bag width | 350~600 mm |

| Bag Length | 500~1000 mm |

| Thickness of Material | 0.1~0.20mm |

Production Performance | |

| Cutting length | Performance |

| 642 mm | 70 Times per minute |

| 692 mm | 65 Times per minute |

| 750 mm | 60 Times per minute |

| 818 mm | 55 Times per minute |

| 900 mm | 50 Times per minute |

| 1000 mm | 45 Times per minute |

| * The mechanical speed is 70 times/min, but the bagging speed depends on the cutting length shown in the table above, the width of the raw material, the strength of the film waist, and the presence or absence of pinholes. |

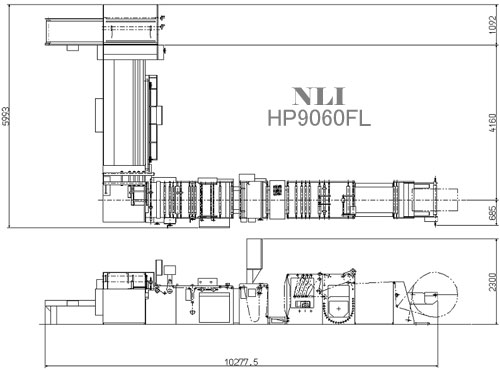

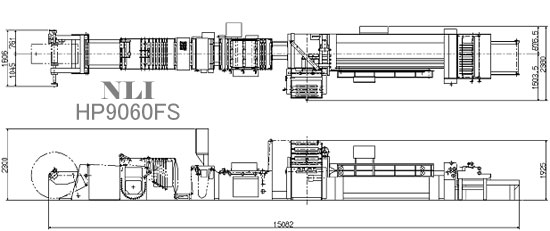

dimension |

○ Dimensions vary according to specifications.

| HP9060FS Belt sealing method/straight line peculiarity To save space on the line, the direction of the film is changed in front of the bottom seal to make the machine straight. The main body (see dimensions) consists of an auxiliary drawer roller part, a pinhole part, a direction changing part, a photocell device part, a drawer roller part, a cutting part and an automatic insertion part. The cutting part of the main body adopts the commercially available single-blade razor throwing method, which is very easy to maintain. It is driven by an AC servo motor with two sets of blades attached to the synchronous belt. The bottom sealing part adopts the single-belt sealing method. The tape sealing speed is extremely high, with a maximum speed of 2 m/min (55 m/min for conventional use). In addition, the sealed part of the bag does not rise and is flat when stacked. |

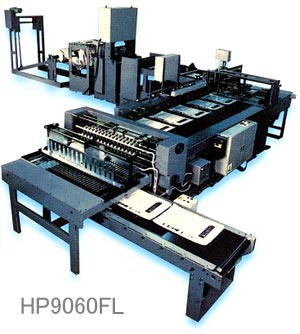

| HP9060FL Tape seal mode, L wire peculiarity The main body consists of an auxiliary drawer roller part, a pinhole part, a photocell device part, a drawer roll part, a cutting part and an automatic insertion part. Since the HP9060FL bends the line into an L-shape, there is no turning part in the straight line (HP9060FS) and is therefore a cost-saving type. The cut section and the bottom seal section have the same specifications as the straight line. |