specification | |

type | MC120 |

Pipe cut length | 400-1200mm |

Pipe width (excluding corner stays) | 300-600mm |

Pipe width | 300-400mm(Conditional maximum500mm) |

Angle brace width | 50-180mm |

Number of floors | Of MAX. 4 Floors |

Base paper width | MAX1230mm |

Base paper diameter | MAX1100mmφ |

ability | MAX250Tubes per minute |

Counting unit processing capacity | 15 bundles per minute |

Drive motor power | 22kW |

Gross machine weight | It's about 26.75 tons |

* Capacity varies depending on paper quality, tube shape, cut length and number of layers. | |

| tubular | |

| 1. | Step cutting |

| 2. | Flush incision |

| 3. | Notch cutting (optional) |

| 4. | Without or with corner braces (optional) |

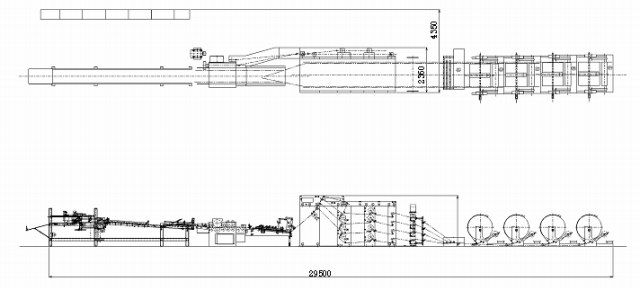

dimension |

○ Dimensions vary according to specifications

| ● Feature 1. We have converted the parts that are considered to need adjustment in the normal mold transformation work to NC, which can shorten the mold replacement time. 2. By improving the alignment of the bag bundles, it will be possible in the future to connect directly to the palletizer after the tubers. 3. By adding a shift in the tool section, the cutting length can be changed from 400 to 1200 to the cutting length simply by operating the handle. In addition, oil stains during shifting are eliminated. 4. Mold change times can be reduced by having a one-click base as standard for horizontal gluing and perforating parts. 5. The top and side covers from each drawer to the entrance of the molding section are standard equipment and are designed to prevent dust from entering. In addition, noise is reduced and safety is improved. | |||

|